This section provides an overview of the TAM9 service manual, outlining its structure and content․ It serves as a foundational guide for understanding the manual’s purpose, scope, and application in maintaining and servicing the TAM9 system effectively․

1․1 Purpose and Scope

The TAM9 service manual is designed to provide comprehensive guidance for the maintenance, troubleshooting, and repair of the TAM9 system․ Its purpose is to ensure optimal performance, safety, and longevity of the equipment by outlining standardized procedures and best practices․ The scope of this manual includes detailed instructions for technicians and engineers, covering diagnostic techniques, maintenance schedules, and repair protocols․ It serves as a primary reference for understanding system components, operational parameters, and safety precautions․ The manual is organized into logical sections, each addressing specific aspects of TAM9 service, from routine inspections to advanced troubleshooting․ By following the guidelines outlined in this manual, users can effectively manage and maintain the TAM9 system, ensuring reliability and efficiency in various operational environments․ This document is intended for trained professionals and assumes a baseline understanding of mechanical and electrical systems․ Adherence to the procedures described herein is essential for maintaining warranty compliance and ensuring operator safety․

1․2 Audience

This manual is primarily intended for trained technicians, maintenance engineers, and service personnel responsible for the installation, operation, and maintenance of the TAM9 system․ It is also a valuable resource for system operators and supervisors who need to understand the technical aspects of the equipment․ The audience includes professionals with a background in mechanical and electrical systems, as well as those involved in troubleshooting and repair․ While the manual is detailed, it assumes a basic understanding of technical terminology and procedures․ It is not intended for untrained individuals or those without prior experience with similar systems․ Adherence to the guidelines in this manual ensures that all users can perform their tasks safely and effectively, maintaining the integrity and performance of the TAM9 system․ By targeting a specific audience, the manual provides focused, relevant information tailored to the needs of professionals working with this equipment․

1․3 Reference Documents

This section outlines the key reference documents that support the TAM9 service manual․ These documents include technical specifications, safety standards, and operational guidelines that are essential for the proper maintenance and servicing of the TAM9 system․ Users are encouraged to familiarize themselves with these resources to ensure compliance with industry standards and best practices․ The reference documents may include the TAM9 system design manual, safety protocols, and manufacturer guidelines for tools and equipment․ Additionally, relevant industry standards and regulations are cited to provide a comprehensive understanding of the system’s requirements․ These documents are intended to supplement the information provided in this manual and should be consulted whenever specific details or clarifications are needed; By referencing these materials, users can ensure that all procedures are performed safely and effectively, adhering to both the manufacturer’s recommendations and applicable laws․ Regular updates to these documents are expected, so it is important to always refer to the most recent versions available․

Safety Precautions

Adhere to all safety guidelines when servicing the TAM9 system to minimize risks․ Wear appropriate PPE, follow proper procedures, and remain aware of potential hazards to ensure a safe working environment and prevent accidents or injuries․

2․1 General Safety Guidelines

Always prioritize safety when servicing the TAM9 system․ Ensure the system is powered off and properly grounded before starting work․ Use approved lockout/tagout procedures to prevent accidental startups․ Wear appropriate PPE, including safety glasses, gloves, and a lab coat, to protect against potential hazards․ Familiarize yourself with emergency shutdown procedures and the location of safety equipment, such as fire extinguishers and first aid kits․ Keep the work area clean and well-ventilated to avoid tripping hazards and exposure to harmful substances․ Avoid wearing loose clothing or jewelry that could get caught in moving parts․ Use tools and equipment only for their intended purposes, and ensure they are in good working condition․ Stay alert and avoid fatigue, as it can impair judgment and reaction times․ Never bypass safety features or ignore warnings, as this can lead to serious injury or equipment damage․ Always follow the manufacturer’s instructions and safety protocols to ensure a safe working environment․ Be mindful of electrical, mechanical, and chemical hazards, and take steps to mitigate them․ Properly label and store hazardous materials, and dispose of waste according to regulations․ Maintain a safe distance from moving components and avoid overreaching․ Ensure all personnel involved in servicing are properly trained and authorized to perform the tasks․ Regularly review and update safety procedures to align with industry standards and best practices․ By adhering to these guidelines, you can minimize risks and ensure a safe and efficient servicing process․

2;2 Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is essential for ensuring safety while servicing the TAM9 system․ Always wear heat-resistant gloves, safety glasses with impact-resistant lenses, and a face mask to protect against debris and chemical exposure․ When working with high-voltage components, use insulated gloves and arc flash protection, including a fire-resistant jacket and pants․ Steel-toe boots are recommended to prevent foot injuries from heavy tools or equipment․ Ensure all PPE meets industry standards and is in good condition․ Regularly inspect PPE for signs of wear or damage, and replace it as needed․ Never perform maintenance without proper PPE, as it is critical for preventing injuries and ensuring compliance with safety regulations․ Always de-energize the system before starting work, and follow all safety guidelines outlined in this manual․ Proper use of PPE is a cornerstone of safe and effective TAM9 servicing․

2․3 Hazardous Materials Handling

Proper handling of hazardous materials is critical when servicing the TAM9 system․ Always identify and label hazardous substances, such as chemicals, fuels, or batteries, and refer to the Safety Data Sheets (SDS) for specific handling instructions․ Wear appropriate PPE, including gloves, goggles, and respirators, when handling potentially hazardous materials․ Ensure good ventilation in the workspace to prevent inhalation of fumes․ Avoid skin contact with hazardous substances, and wash hands thoroughly after handling․ Store hazardous materials in designated, well-ventilated areas away from ignition sources․ Dispose of hazardous waste in accordance with local, state, and federal regulations․ In case of spills or leaks, contain the material immediately and follow cleanup procedures outlined in the SDS․ For emergencies, have a spill response kit nearby and evacuate the area if necessary․ Always follow environmental and safety regulations to minimize risks to personnel and the environment․

Tools and Equipment

This section outlines the essential tools and equipment required for servicing the TAM9 system․ It covers specialized tools, common equipment, and maintenance practices to ensure proper servicing and compliance with technical specifications and safety standards․

3․1 Specialized Tools Required

The TAM9 service manual specifies several specialized tools necessary for effective servicing․ These include a torque wrench for precise bolt tightening, a multimeter for electrical diagnostics, and a hydraulic press for component disassembly․ Additionally, custom sockets and adaptors are required for specific TAM9 components․ Calibration tools, such as a micrometer and dial gauge, ensure accurate measurements during repairs․ A laptop with proprietary software may also be needed for system diagnostics and firmware updates․ Proper use of these tools is critical to maintain system integrity and ensure safety․ Always refer to the manufacturer’s guidelines for tool specifications and usage procedures․ Failure to use the correct tools may result in equipment damage or unsafe operating conditions․ Regular calibration and maintenance of these tools are essential to uphold precision and reliability during servicing․ Adherence to these requirements ensures compliance with industry standards and guarantees optimal performance of the TAM9 system․

3․2 Common Tools and Equipment

Common tools and equipment are essential for performing routine maintenance and repairs on the TAM9 system․ These include basic hand tools such as wrenches, screwdrivers, pliers, and punches․ Additionally, a socket set and ratchet are frequently used for bolt and nut operations․ Air-powered tools, like impact wrenches, may be necessary for high-torque applications․ Measuring tools, such as calipers and depth gauges, are critical for precise adjustments and inspections․ A workbench with vise and storage for small parts is also recommended to keep components organized during servicing․

- Wrenches (adjustable and fixed sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and slip-joint)

- Socket set with ratchet and extensions

- Calipers and depth gauges

- Air-powered tools (e․g․, impact wrench)

While specialized tools are required for certain tasks, these common tools form the backbone of TAM9 servicing, enabling technicians to perform a wide range of procedures efficiently and safely․ Regular maintenance of these tools ensures their reliability and accuracy during critical operations․

3․3 Equipment Calibration and Maintenance

Regular calibration and maintenance of TAM9 equipment are crucial for ensuring accuracy, reliability, and optimal performance․ Calibration should be performed at intervals specified in the manufacturer’s guidelines or whenever deviations in readings are detected․ Use only approved tools and reference materials to ensure precision․ Maintenance routines include cleaning sensors, lubricating moving parts, and checking for wear and tear․ Always follow the recommended procedures outlined in this manual to avoid equipment damage or measurement errors․ Proper documentation of calibration and maintenance activities is essential for tracking and compliance purposes․ Failure to adhere to these practices may result in inaccurate readings, safety hazards, or equipment failure․ Always refer to the TAM9 service manual for detailed step-by-step instructions and safety precautions before performing any calibration or maintenance tasks․ Regularly updated schedules and procedures ensure the TAM9 system remains in top working condition․

Diagnostic and Troubleshooting

This section outlines diagnostic methods to identify and resolve TAM9 system issues․ It provides a systematic approach to troubleshooting, including error code interpretation and log analysis, to minimize downtime and ensure reliable operation․

4․1 Basic Diagnostic Procedures

The basic diagnostic procedures for the TAM9 system involve a systematic approach to identify and isolate faults․ Start with a visual inspection of connectors, cables, and components for signs of damage or wear․ Use diagnostic tools like multimeters or system-specific software to measure voltage, current, and resistance․ Check error logs and event codes stored in the system memory to pinpoint potential issues․ Verify communication between modules by reviewing network diagnostics․ Perform functional tests on sensors, actuators, and other critical components to ensure proper operation․ Consult the service manual for specific test procedures and expected values․ Always follow a structured troubleshooting flowchart to minimize guesswork and ensure accurate fault identification․ Document all findings and refer to advanced diagnostic techniques if initial tests do not resolve the issue․ This methodical process ensures efficient and effective problem-solving, reducing downtime and maintaining system reliability․

4․2 Advanced Troubleshooting Techniques

Advanced troubleshooting techniques for the TAM9 system involve detailed analysis and specialized tools to resolve complex issues․ Begin by utilizing advanced diagnostic software to monitor real-time system performance and capture detailed logs․ Perform in-depth analysis of error codes, system event logs, and sensor data to identify patterns or anomalies․ Use specialized tools like oscilloscopes or signal generators to test and verify the integrity of critical components․ Conduct advanced network communication tests to diagnose issues with data transmission or module interactions․ Apply system-specific troubleshooting algorithms provided in the service manual․ For intermittent faults, employ techniques such as thermal imaging or stress testing to replicate conditions under load․ Consult detailed schematics and wiring diagrams to trace signal paths and identify potential failure points․ If necessary, perform system resets or reinitialization procedures to restore baseline functionality․ Always refer to the manufacturer’s guidelines for advanced diagnostic techniques to ensure accuracy and safety․ These methods allow for precise identification and resolution of complex system malfunctions․

4․3 Common Issues and Solutions

This section outlines frequently encountered issues with the TAM9 system and provides practical solutions to address them effectively․ Common issues include error codes, communication faults, and sensor malfunctions․ For error codes, refer to the troubleshooting matrix in the manual to identify the root cause․ Communication issues often arise from loose connections or corrupted software; ensure all cables are secure and perform a system reset if necessary․ Sensor malfunctions may require calibration or replacement, following the procedures detailed in the maintenance section․ Additionally, intermittent system freezes can be resolved by updating firmware to the latest version․ Always verify solutions against the manufacturer’s guidelines to ensure compatibility and safety․ By addressing these common issues promptly, operators can minimize downtime and maintain optimal system performance․ Regular maintenance and updates are crucial to preventing recurring problems․ Refer to the diagnostic flowcharts for step-by-step guidance on resolving specific faults efficiently․

Maintenance Procedures

This section outlines the essential maintenance procedures for the TAM9 system, ensuring optimal performance and longevity․ It covers routine checks, inspections, and lubrication schedules to prevent operational issues and maintain efficiency effectively․

5․1 Scheduled Maintenance Intervals

Scheduled maintenance intervals are critical for ensuring the TAM9 system operates efficiently and reliably․ These intervals are determined based on usage frequency, environmental conditions, and manufacturer recommendations․ Regular checks should be performed daily, weekly, and monthly, focusing on key components such as filters, belts, and fluid levels․ Annual maintenance typically includes more comprehensive inspections and replacements of wearable parts․ Adhering to these schedules helps prevent unexpected breakdowns, reduces downtime, and extends the system’s lifespan․ Always refer to the detailed maintenance charts and tables provided in this manual for specific interval guidelines tailored to your TAM9 model and operational demands․ Proper scheduling ensures optimal performance, safety, and cost-effectiveness over the system’s service life․

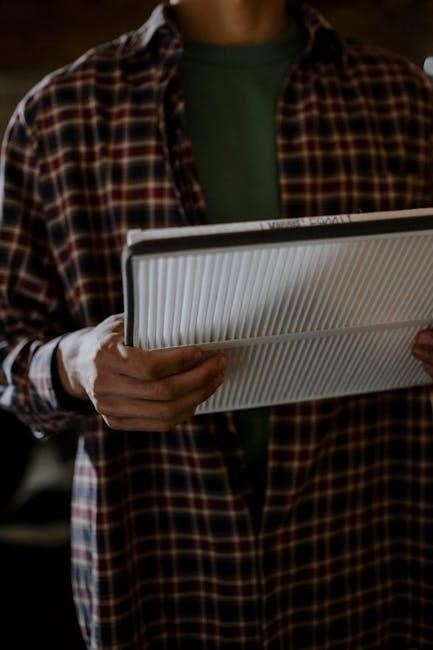

5․2 Routine Checks and Inspections

Routine checks and inspections are essential for maintaining the TAM9 system’s optimal performance and preventing potential issues․ Begin with a visual inspection of all components, including electrical connections, hoses, and belts, to ensure they are secure and free from damage․ Check fluid levels, such as hydraulic and coolant, and top them off as needed․ Inspect air filters and clean or replace them according to the manufacturer’s recommendations․ Test all safety mechanisms to ensure they function correctly․ Use diagnostic tools to monitor system pressure, temperature, and vibration levels․ Document any abnormalities or wear and tear in a maintenance log․ Perform these checks daily before startup and during shutdown to identify early signs of deterioration․ Addressing minor issues promptly can prevent major breakdowns and extend the system’s operational life․ Always follow the inspection checklist provided in this manual for a comprehensive evaluation․

5․3 Lubrication and Cleaning Procedures

Regular lubrication and cleaning are critical for ensuring the TAM9 system operates efficiently and maintains its longevity․ Apply high-quality, water-resistant grease to all moving parts, such as bearings and hinges, every 500 hours of operation or as specified in the maintenance schedule․ Use a clean, lint-free cloth to remove dirt, grime, and old grease before applying new lubricant․ For electrical components, ensure they are free from dust and moisture by gently cleaning with a dry brush or compressed air․ Avoid using harsh chemicals, as they may damage sensitive surfaces․ Clean the exterior and interior of the TAM9 system periodically to prevent debris buildup․ Inspect grease fittings and replace them if damaged to maintain proper lubrication flow․ Always refer to the recommended lubricant specifications in the manual to ensure compatibility․ Regular cleaning and lubrication not only prevent wear and tear but also reduce the risk of system downtime and costly repairs․

Repair and Replacement

This section outlines procedures for repairing and replacing TAM9 components, ensuring optimal system functionality and longevity through proper techniques and adherence to safety guidelines․

6․1 Disassembly and Reassembly Procedures

Disassembling and reassembling the TAM9 system requires careful adherence to specific steps to ensure proper functionality and prevent damage․ Begin by preparing a clean, organized workspace and gathering all necessary tools․ Document the location of each component before disassembly to facilitate accurate reassembly․ Remove external fasteners and connectors in a systematic order, starting from the outermost components․ Use specialized tools to release locking mechanisms or seals without causing damage․ Label and store small parts securely to avoid loss․ During reassembly, follow the reverse sequence, ensuring all components are aligned correctly and fasteners are tightened to the specified torque․ Pay particular attention to sensitive electronics and moving parts, handling them with care to prevent wear or malfunction․ After reassembly, perform a thorough inspection to verify all connections and alignments are correct․ Finally, test the system to ensure it operates as intended before returning it to service․

6․2 Component Replacement Guidelines

Replacing components in the TAM9 system requires adherence to specific guidelines to ensure functionality and safety․ Always use genuine or approved replacement parts to maintain system performance and warranty validity․ Before starting, disconnect power and ensure the system is in a safe state․ Follow the disassembly procedures outlined in Section 6․1 to access the component․ Document the location and orientation of connectors and fasteners to facilitate accurate reinstallation․ Handle sensitive electronic components with anti-static precautions to prevent damage․ When installing the new component, ensure proper alignment and secure it using the recommended torque specifications․ Reconnect all cables and connectors in the reverse order of disassembly, verifying each connection for integrity․ After replacement, perform a thorough inspection and functional test to confirm the system operates correctly․ Dispose of defective components responsibly, following environmental regulations․ Finally, update maintenance records with details of the replacement for future reference․